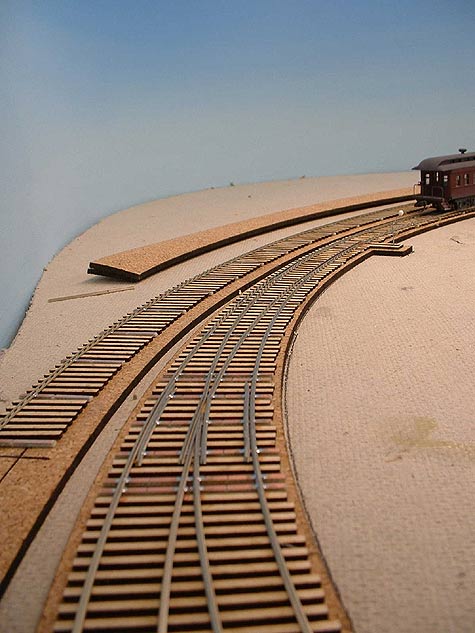

Track laying progress…

Back to the bench….

I found it a bit ironic that finishing the trackwork was holding up production on my layout, so I figured I should get back to it.

Necessity being the mother of invention (or is it the other way around?) I decided I had had enough of spiking trackwork. Using the fixtures, turnouts can be constructed without any spikes, and this is something I have found really helps me increase accuracy and reliability of my trackwork by eliminating the need to push spikes into the ties, a step that always ended up mis-aligning the rails. Building a double deck layout is hard enough on the back (and front and sides), spiking trackwork from a ladder in a contorted position seems to get more difficult for me every year.

Spikeless handlaid track system

Above is a picture of my alternative to building hand laid track with spikes. Building turnouts at my workbench is a serious improvement to building trackwork, much easier to work in comfort and I wanted to extend this method to all my track laying.

This system has been in development for some time now, and I wanted to give it a thorough test on my own layout first. So far I am very happy with the results!

The system includes a fixture with two fixed radii of any size, and one section of straight track. Tie pockets are spaced every 6th tie for PC board ties. PC board ties cut to 8.5 scale feet in length, pre-grooved for electrical isolation, on both sides, and placed into the pockets and rail soldered to the ties. Staggering joints between lengths of rail will produce unlimited lengths of straight or curved track sections.

Flexible hand laid track?

Where this system really shines though is its ability to produce lengths of flexible track for unknown or compound radii, or easements into and out of fixed radii. Using the straight track portion of the fixture, one length of rail is soldered to the PC board ties and removed from the fixture. This length of track will be flexible. Add to this our laser cut flexible lengths of ties (available soon), glued in place with Pliobond Industrial contact adhesive,between the PC board ties and you will have a length of flexible trackwork with ties that will “splay” or “contract” with the flexing of the rails.

This is glued to your roadbed with carpenters glue and held in place with pins until the glue sets up. The second rail is then soldered in place to the PC board ties using Micro Engineering 3 Point track gages This will hold the rail in perfect gauge while soldering. This system is quick and very accurate and almost indestructible. You could run a real train over this trackwork! (note: do not run a real train on this trackwork)

Available soon…

When released, this system will be available for all scales and gauges, with any radii requested. Fixtures with just radii will also be available.

Image copyright Tim Warris 2004

Posted by: | 11-10-2004 | 12:11 PM

Posted in: Uncategorized

Nice blog ! Enjoyed reading the thread ! Great photos – never really thought about handlaying track thinking :Too Hard” – but you make it look pretty simple and straight forward.

Mike

Tim,

Awesome site!

I was on the FAST TRACKS site and could not locate any straight/curve track templates as you have shown in your picture. Only one mention of a curved turnout. What is the stock number of what you have pictured, and where can they be found on the FAST TRACKS site?

Did you look into the Central Valley tie strips and turn outs when evaluating your track selection?

I’m new to this as far as builing a layout goes, but I’ve been looking into both Central Valley and FAST TRACKS, as they seem the most detailed. I may only build a 22 X 4 “layout”, and am looking for the most detailed, yet reliable track available.

Thanks!

Joe Mehalic

Great Web-site. Have enjoyed looking at everything on the Fast Tracks

site. Was kind of wondering about the curved and straight tracks made

with the jigs. I use code 100 flex-track now, and like it. You wouldn’t be able to bend the tracks made with the FAST TRACK jigs.

However, ‘GREAT PICTURES”. Keep up the good work. You have a great idea here.

Looks great Tim!

Question is – at this point does it count as hand-laid track anymore? 😉

I handlay my N-scale track and one of the things I really like about the look is the random edges and casual layout of the ties. That said, I’ve limited my efforts to shadowbox layout scenes with multiple boxes forming the layout. Your solutions look great should I ever obtain enough space to create an integrated layout.

Tim, Exlent soluition to “hand Laying” track. I see where it would be of great service in hidden, return, and stageing yards and loups where Mr. Murphy is at his best.

“Tim, Exlent soluition to “hand Laying” track. I see where it would be of great service in hidden, return, and stageing yards and loups where Mr. Murphy is at his best.”

It does work very well, and ensures accurate and consistent gaging, which is very desirable for hidden trackage.

I am hoping to have this system available early this coming year!

-Tim