1st Blog post

Might as well start somewhere….

Image Copyright 2004 Tim Warris

Several months after purchasing our laser cutter to produce our Quick Sticks Laser Cut Ties I finally got around to playing with it, other than producing ‘revenue’ stuff…

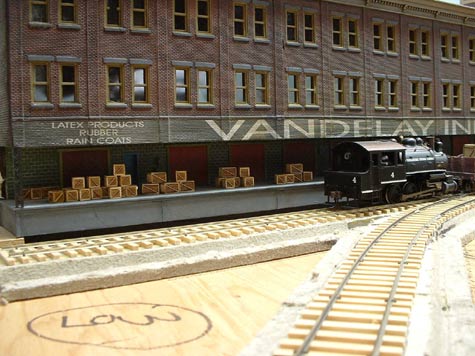

I made some laser cut crates for freight car loads, these are made from two separate pieces of 1/64th plywood, glued on top of each other. One of the neat features of laser cutters is the dark edge they create when cutting, makes for a very visible edge and a lot of ‘dimension’ on the finished parts….

Little crates

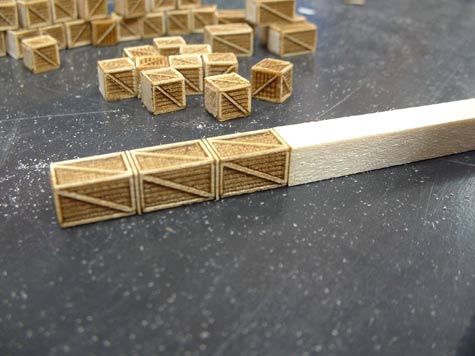

Another approach was to ‘engrave’ crates from solid pieces of wood. One thing not seen to often in laser cut kits are engraved parts. Laser cutters are usually marketed as ‘laser engravers’ mainly used in the sign and trophy industires, adjusting power settings will allow them to cut as well, the method used to produce kits. Engraving is a very slow process, and unsuited to production work, which is why the technique is rarely used in kits.

Using the engraving technique I was able to mass produce smaller crates, 10 at a time on some 1/4″ basswood, rotating it a quarter turn each time. Once complete I cut them into individual crates. A quick way to make several nice looking crates for a loading dock…

Image Copyright 2004 Tim Warris

Image Copyright 2004 Tim Warris

Posted by: | 11-04-2004 | 05:11 PM

Posted in: Uncategorized

Wow!

Where can I get some of these crates?

I have a huge layout and these would be ideal, I’d say about 2000 pcs.

Costs?

Tim, those crates are great. I too could use a whole bunch of them. I have an outdoor loading dock scene like yours where I could easily use 100-200 of those crates. Let me know if you intend to make and sell them!

Pleased to see something new and ‘great’ on your web – site as you told me to look into whilst talking to you and Clark at Ancaster .

I am planning a N – Scale layout using either code forty or fifty – five track . However much of the layout will consist of a long and yet to be determined gentle curve . This severely limits the use of one of your turnout jigs , unless you can devise a curved turnout jig of varying radii !

However , congratulations on producing some excellent products !

Ian Maynard

Hi Tim

I workbenches can be related our’s have to be brothers.

Can you tell me about your laser cutter. I have spent hundreds of hours trying to find parts and pieceses that I could make if I had the facility to cut the fine lines.

Thanks for the magnificent products and caring from you and the family.

Lew